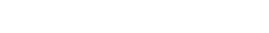

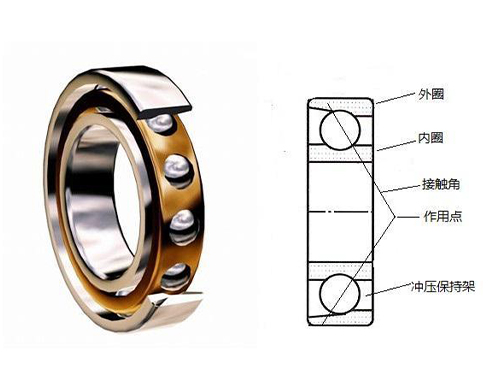

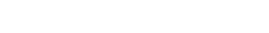

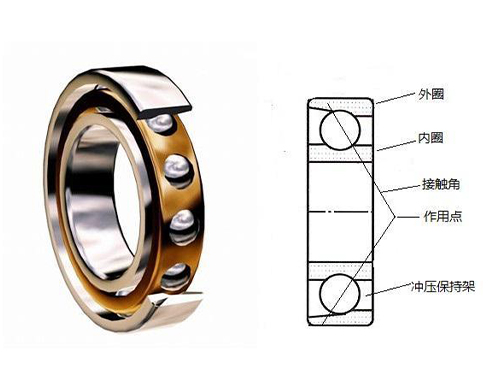

Angular contact ball bearings can bear both radial and axial loads. Can work at high speed. The larger the contact Angle, the higher the axial bearing capacity.

The installation forms of angular contact ball bearings are back-to-back, face to face and series arrangement. The outer ring of angular contact ball bearing is thick on one side and thin on the other. The thick side is called the "back", and the thin side is called the "face". It should be noted that the installation of angular contact ball bearings is mostly paired installation, and preloading is required. If the installation is good, the working accuracy and bearing life of the main engine can be greatly improved. Otherwise, not only the accuracy cannot meet the requirements, but also the life will be affected.

1, back-to-back (the wide end face of the two bearings relative) installation, the contact Angle of the bearing along the direction of the rotation axis diffusion, can increase the radial and axial support Angle rigidity, the maximum deformation resistance;

2, face to face (the narrow end face of the two bearings are opposite) installation, the contact Angle of the bearing converges to the direction of the axis of rotation, and the ground bearing Angle is less rigid. Because the inner ring of the bearing extends out of the outer ring, when the outer rings of the two bearings are pressed together, the original clearance of the outer ring is eliminated, which can increase the preloading load of the bearing;

3. When arranged in series (the wide end faces of the two bearings are in one direction), the contact angles of the bearings are in the same direction and parallel, so that the two bearings can share the working load in the same direction. However, when using this installation form, in order to ensure the axial stability of the installation, two pairs of bearings arranged in series must be installed opposite to each other at both ends of the shaft.